This is what I mean. Here a typical pairing of 22.20 volt six-cell LiPo battery-packs are set in the forward left corner of the air vehicle, with the cables set to address an ESC positioned nearest the motor to be fixed centrally upon the perimeter tubing seen top of the photo. Wrapped round the packs is velcro fastening tape to size the battery tray formed of two off-cut lengths of angle-alloy.

The brackets are marked to show how they line up with a row of perforations, so that a couple of holes can be drilled to house the pairs of pop-rivets that secure them too the safety grille. Afterward two short lengths of velcro tape are riveted to one of those brackets, beside the perimeter tubing itself. You may wish to drill and fasten the latter length of tape PRIOR to fitment of the corresponding bracket opposite, so as to make room for the hand-drill.

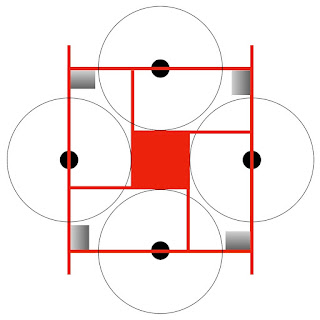

As with most operations during this build, repeat a further three times. Battery-packs are located in these positions principally because it's much easier to support their weight when they are placed on the top-side of the airframe than suspended beneath. They are also set at a distance from the pilot-operator, so that the risks associated in (a) connecting the batteries whilst clear of each propeller's arc and (b) fire during their operation is reduced to a minimum.

It also distributes mass evenly around the airframe, albeit at the expense of reducing the manoeuvrability by the same degree due to dispersing it furthest from the C of G: as ever then it's a case of 'Keep it simple, stupid'.